FMV50

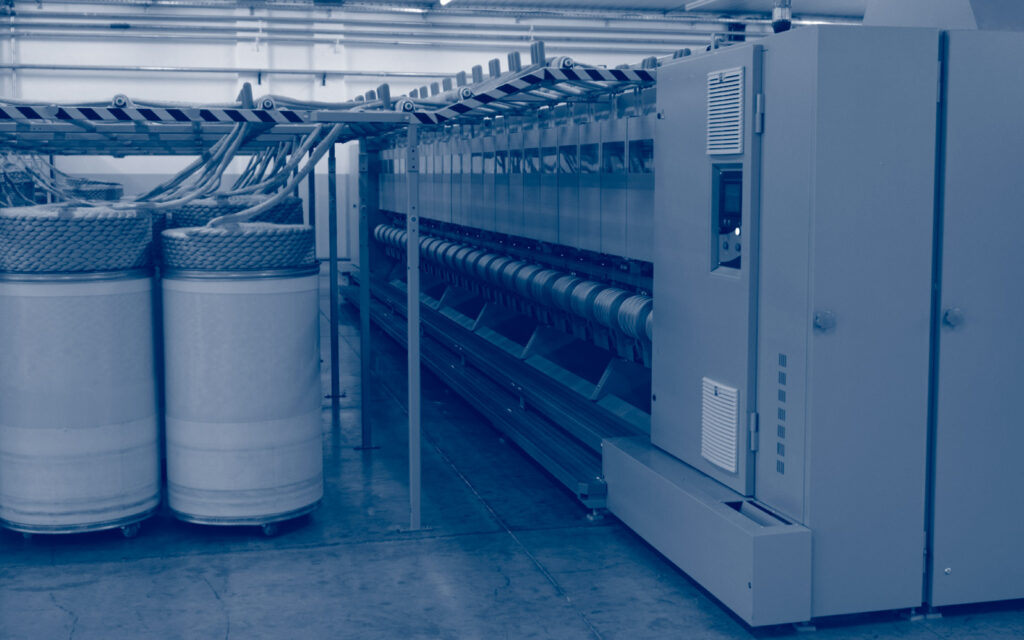

The mechatronic vertical rubbing frame

The FMV50 is the evolution of the FMV40 with additional axis based on mechatronic technology which facilitate use and maintenance. Moreover the new 50 model is prepared to the Industry 4.0 with a complete data collection. The Internet connection allows machine diagnostic by our customer service.

The major interest of this mechatronic technology is to reduce mechanical settings and operators’ interventions. That is why many settings are electronically monitored in order to enhance precision and responsiveness.

Model FMV50S: tubes of 300 mm, bobbins containing up to 4.5 kg of material.

Model FMV50L: tubes of 330 mm, bobbins containing from 5 to 6 kg of material.

The FMV50 vertical rubbing frames are intended to produce rubbed rovings in the count range Nm 0.66 to 6. They offer outstanding performances up to 275 m/min with only one rubbing level. The vertical rubbing frames are fully automatic, reliable, flexible and productive, and are perfectly suited to modern production lines.

The FMV50 rubbing frames can be equipped with 3 different types of interchangeable drafting systems. Designed by n. schlumberger, they have the following characteristics:

A: long drafting system with control barrels on apron

B: short drafting system with double apron

C: short drafting system with control barrels on apron

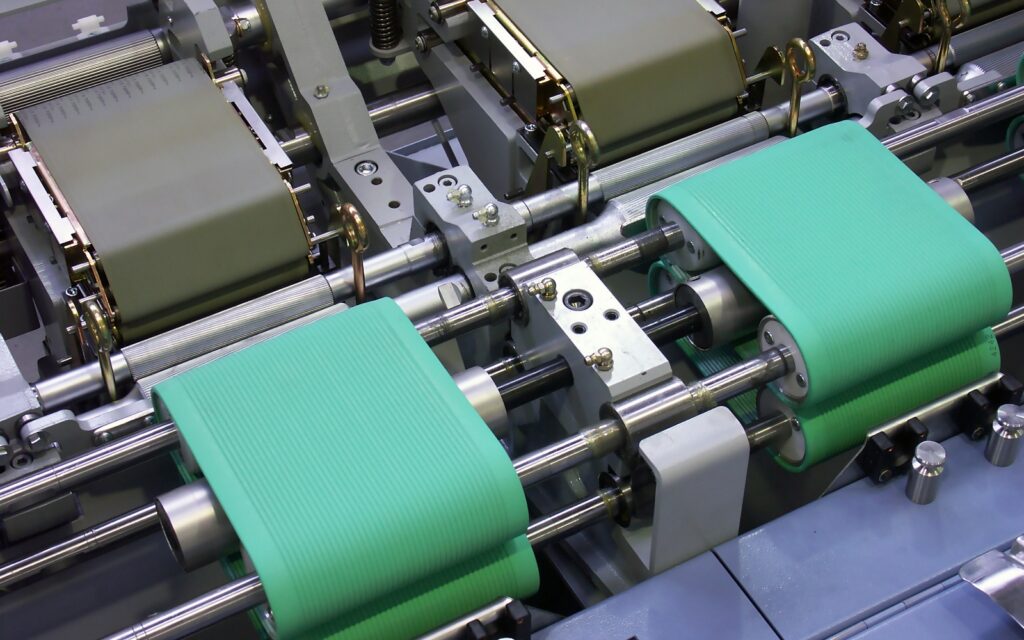

On the FMV50, the rubbing is performed by a single pair of aprons. The single row rubbing always permitted to produce the quality rovings which fulfil the user’s requirements. The number of rubs is adjustable electronically from 2.5 to 10 rubs/m in increments of 0.1. A precise design of the rubbing drive and the use of aprons adapted to high speeds makes it possible to work up to 1500 rubs/min.

The new suction system with two filtering bags replaces the traditional suction box. This easier cleaning process gives the filter better durability. By doubling the filter surface it also helps to be more efficient during the suction process and the suction power is adjustable.

Another innovation concerns the screen monitor. With a new size of 15”, a large amount of information can be displayed in real time. The documentation of the machine is accessible via the screen as well as useful data like tensions or power consumption.

FMV40

The FMV40 vertical rubbing frames series are the traditional generation of rubbing frames for spinning preparation intended to win challenges of performance and quality.

Model FMV41: tubes of 300 mm, bobbins containing up to 4.5 kg of material.

Model FMV42: tubes of 330 mm, bobbins containing from 5 to 6 kg of material.

The distance between rubbing and winding is increased so that a larger tube can be used without any risk for the textile quality.

The FMV40 vertical rubbing frames are intended to produce rubbed rovings in the count range Nm 0.66 to 6. They offer outstanding performance up to 275 m/min with only one rubbing level. The vertical rubbing frames are fully automatic, reliable, flexible and productive, and are perfectly suited to the modern production lines.

The FMV41 and 42 rubbing frames can be equipped with 3 different types of interchangeable drafting systems. Designed by n schlumberger, they have the following characteristics:

A: long drafting system with control barrels on apron

B: short drafting system with double apron

C:short drafting system with control barrels on apron

On the FMV41 and 42, the rubbing is performed by a single pair of aprons. The single row rubbing always made it possible to produce high-quality rovings which fulfil the user’s requirements. The number of rubs is adjustable: 5 – 5.8 – 7 and 8 per meter. A precise design of the rubbing drive and the use of aprons adapted to high speeds make it possible to work up to 1500 rubs/min. Simple, the rubbing system features low maintenance costs.

FM20

The FM20 horizontal rubbing frames are preparation finishers intended to produce rubbed rovings in the count range Nm 0.66 to 5.5 or even finer. They process in all safety wool, long staple chemical fibres and blends. Particularly appreciated in flexible production units for small batches, the FM20 horizontal rubbing frames reach a speed of 220 m/min.

The FM20 rubbing frames are fitted with a drafting system designed by n. schlumberger. The roving rubbing is achieved by a pair of grooved rubber aprons driven by cylinders fitted on ball bearings.

The FM20P horizontal rubbing frames are characterised by their can deliveries. They process under the best conditions wool and long staple chemical fibres in the count range Nm 0.4 to 2 and can reach a delivery speed over 220m/min.

Like the other rubbing frames in our range, the FM20P’s stand out due to their high reliability, their operational flexibility and their high productivity.

The FM20P horizontal rubbing frames with can delivery are very efficient as fore-finisher in the preparation units for fine count yarns or direct

BM21

For delicate material or material without cohesion like mohair, silk or flax, the BM21 roving frame is the solution. The BM21 is also used in the fancy yarn industry.

The BM21 roving frame for spinning preparation produces twisted rovings at speeds up to 120 m/min according to the material, the twist and the count. This corresponds to a maximal flyer speed of 1800 rpm.

Built for high speeds with an absolutely precise bobbin built-up, the BM21 roving frame is fitted with a drafting system comprised of an apron and barrels.

These machines are available up to 64 spindles, in sections of 16 in a semi-automatic version.