Innovation in carding

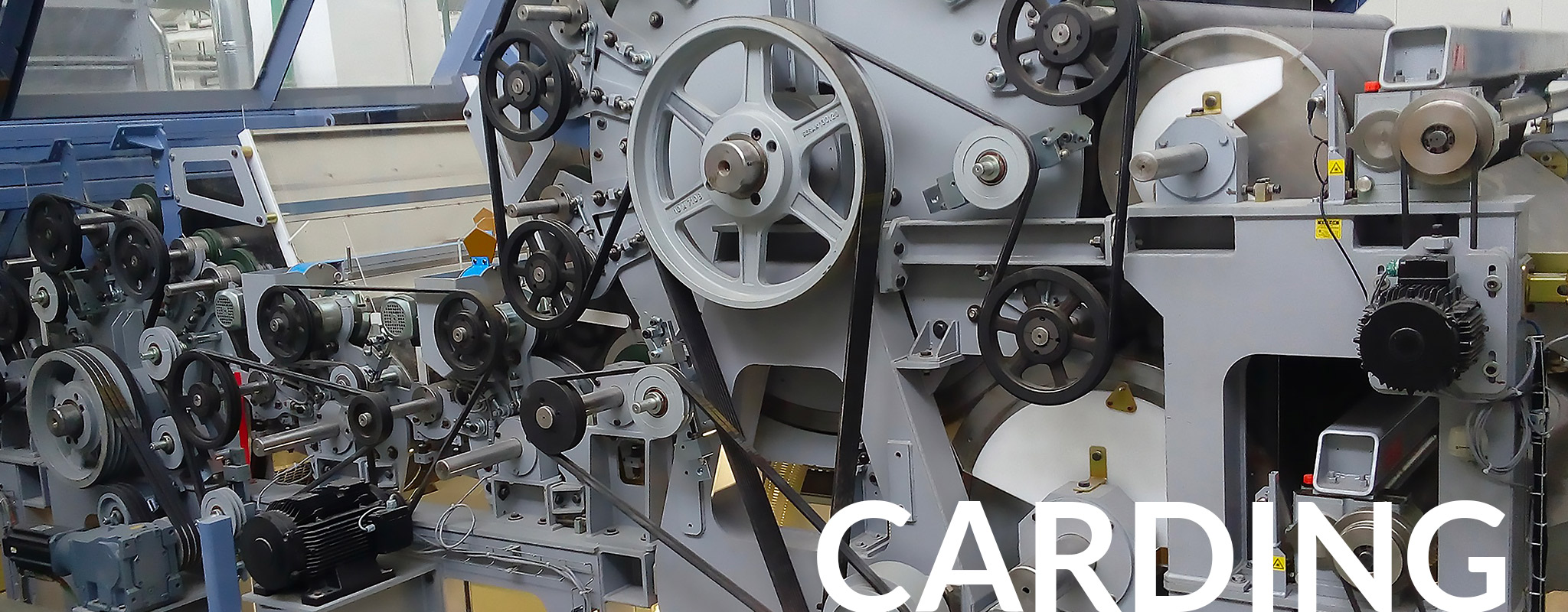

The various n. schlumberger cards are designed to process natural fibres like wool or mohair, as well as synthetic fibres, silk noil or flax tows.

All the n. schlumberger cards offers the user multiple advantages:

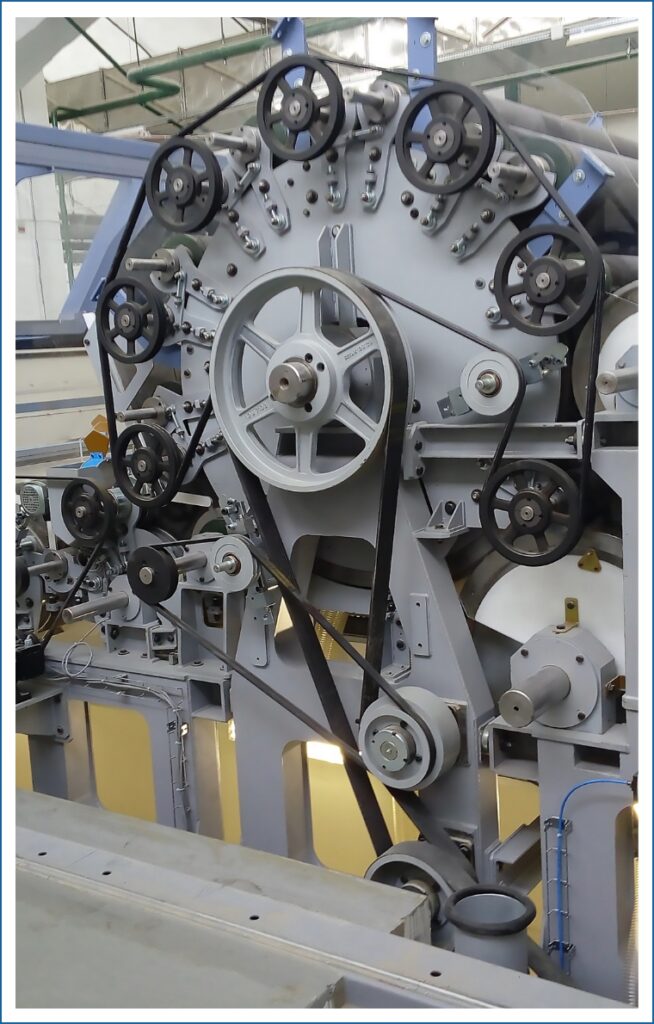

![]() Mechanical simplicity, sturdy construction ensuring a dependable long term operation and minimized downtime for maintenance

Mechanical simplicity, sturdy construction ensuring a dependable long term operation and minimized downtime for maintenance

![]() Safety and ease of use with centralized readout and control of the various production parameters from the operator’s desk

Safety and ease of use with centralized readout and control of the various production parameters from the operator’s desk

![]() Excellent quality of the output sliver delivered

Excellent quality of the output sliver delivered

![]() High production level, achieved by high cylinder speeds and optimized use of the cylinder surface

High production level, achieved by high cylinder speeds and optimized use of the cylinder surface

![]() Two different widths: 2.50 and 3.50 m

Two different widths: 2.50 and 3.50 m

![]() Two morels cylinders for the processing of scoured wool

Two morels cylinders for the processing of scoured wool

![]() Continuous flow volumetric hopper feeder

Continuous flow volumetric hopper feeder

![]() Single or double doffers

Single or double doffers

![]() Drafting head ensuring an optimum fibre control

Drafting head ensuring an optimum fibre control

![]() Delivery with automatic can changing

Delivery with automatic can changing

![]() Integrated centralized suction system

Integrated centralized suction system

![]() Centralized readout and control of the various production parameters from the operator console.

Centralized readout and control of the various production parameters from the operator console.

Worsted card

Designed to process wool and other natural fibres such as mohair with two morels cylinders for the processing of scoured wool.

Semi-worsted card

Suited to the processing of both natural and synthetic fibres. The semi-worsted card can be incorporated into any semi-worsted process line for carpet or knitting yarns.

Flax card

This card is tailored to the process of flax tow and bast fibres. It is provided with a bale opener, especially suited to the bast fibres. This card is only available in 2.5 m working width.

Feeder

The continuous flow volumetric feeder determines the uniform distribution of fibres. It is achieved by high precision machines which accurately monitor the fibre control.

To complement their high performance feed systems and particularly on small batches with short manufacturing cycles, the cards can be supplied on optional with an infeed autoleveller.

Doffer

The cards are equipped with single or double doffers on delivery: detaching rollers or combs makes it possible to process all type of fibres.

Access

Easy access to all the card drives and rollers to reduce the time required for maintenance operations: removable side guards and quick and easy opening of the grids under the card without losing their settings.

Variable speed motor drives to allow operational changes of sliver weight, rate of production and carding intensity.

Drafting

Located at the delivery end of the machine, the drafting head allows adjustment of the sliver weight.

Suction system

To preserve environmental air-quality objectives in the mill, the cards are supplied with an integrated suction system. This includes several extractor nozzles, placed width-wise and above the breast roller and main cylinder, as well as in the web and drafting head consolidation zone.

Touch screen

Controlling of the card from the supervisory control panel. Safety and ease of use with centralized adjustment of measured parameters.